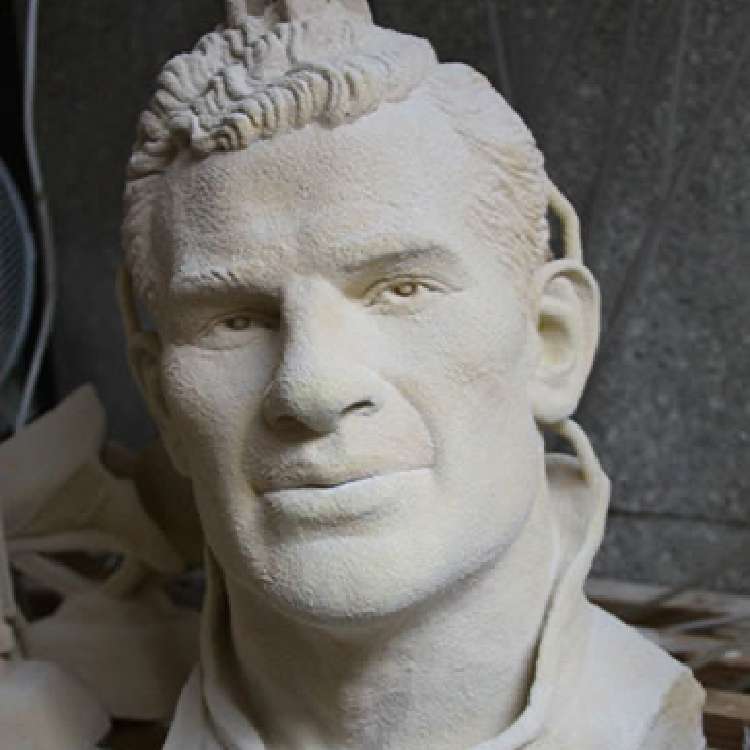

The First step of this labour-intensive process is to first create a sculpture. This is done using either clay or wax often built around an armature for stability.

Once the sculpture is completed it will then be cut into pieces depending upon the size and complexity of the piece. The moulds are typically two parts and can consist of fibre glass, rubber or plaster. Each sculpture is unique so the number of moulds will vary from one up to twenty.

Once the moulds are completed they are used to create a Lost wax pattern. This is done by slurring boiling hot wax around inside the mould. This is repeated until the wax is the correct thickness. It is very important that the wax does not contain any air bubbles. The wax is left to cool and then removed from the mould. The wax is assembled, worked and prepared for mounting and spruing.

Following this ceramic shelling process, this is completed by covering the lost wax slurry mix and coated with ceramic powder. This process is repeated several times. Each layer must be allowed to dry completely before the next layer is applied. This process takes several days to complete. Some pieces can have as many as ten layers.

When the shelling process is complete the lost wax is burnt out from the ceramic shell. This entails heating the ceramic shells until they are glowing orange. The lost wax melts and pours out of the ceramic shell. Once they are cool the shells are then prepared for the bronze pour.

Bronze is then heated to temperatures in excess of 1000⁰C. When it is molten it is poured into the ceramic shells and left to cool.

Once cooled the ceramic shell is then knocked away leaving the bronze which is then ready for finishing.

Finishing entails cutting off the sprues, shot blasting, chasing the detail of bronze sculpture. Where the sculpture has been cut into smaller pieces, this means these must be welded together. This takes a lot of work making sure each piece locates correctly and once welded together, the welds have to be chased out and re-sculpted. This can take weeks to complete this process.

The completed bronze sculpture is now ready for the next and final process which is the patina. The sculpture is heated and chemicals are applied to the surface of the bronze. This process colours the bronze. There are a variety of chemicals that can be used, each giving a different colour. This can take several days before the desired colour is achieved. A wax is then applied to protect it.

The bronze is then ready for delivery